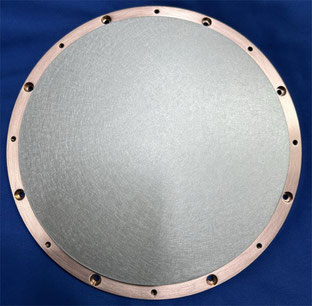

Gold-tin (AuSn) target

An alloy sputtering target consisting of gold (Au) and tin (Sn), mainly used in thin film deposition processes such as electron beam deposition and magnetron sputtering (PVD).Its unique low melting point, high thermal conductivity and excellent welding performance play a very important role in the fields of microelectronic packaging, optoelectronic devices and semiconductors.

1. Characteristics

1) Low melting point and excellent welding performance

・The eutectic melting point of gold-tin alloys such as Au 80 Sn 20 is only 280°C.

・The AuSn₄ intermetallic compound formed after welding has high strength to withstand high temperature environments

such as power device packages.

2) High thermal conductivity and electrical conductivity

・The thermal conductivity of AuSn₄ alloy is as high as 57 W/(m-K), which is superior to that of ordinary solders such as SnAgCu, making it suitable for the heat dissipation demands of high-power electronic devices.

・The alloy has low resistivity (~ 16 μΩ-cm) and is suitable for high-frequency signal transmission.

3) High purity and low oxygen content

・AuSn targets for industrial use have a purity of ≥99.99%, and some high-end applications (e.g., laser packages) require

Au purity of ≥99.999%.

・Strict control of oxygen content (<100 ppm) to prevent porosity and soldering during welding.

4)Excellent corrosion resistance

5)Adjustable component ratios

・General composition ratio: Au 80 Sn 20 (eutectic alloy), Au90Sn10

2. Main applications

1)Interconnection of microelectronic packages and chips

・Used for chip bonding of laser diodes (LD) and light emitting diodes (LED) to provide a highly reliable heat conduction path.

・Replaces conventional solder in power device (IGBT, MOSFET) packages to improve heat dissipation performance

and long-term reliability.

2) Optoelectronic devices and semiconductors

・Hermetic packages for fiber optic communication devices such as DFB lasers to prevent moisture erosion.

・Used as welding material for infrared detectors and MEMS sensors to ensure high-precision assembly.

3) Aerospace and defense electronics

・Used for welding high-frequency components in satellite and radar systems, adapting to extreme temperature

changes (-55°C to 200°C).

・Provides stable electrical signal connections in missile guidance systems.

4) Medical electronics

・Used for capsule welding of implanted medical devices such as cardiac pacemakers to meet biocompatibility requirements.

5) High-reliability electronic assembly

・Alternative to conventional tin-lead solder (RoHS exemption field) used in automotive electronics, industrial controls,

and other long-life demand scenarios.